With

regards to systems administration hardware, there is one name that is

continually improving and that everybody thinks about, Cisco Systems. Cisco is

one of the fundamental, if not the greatest, designer and maker of systems

administration hardware on the planet. Cisco has been creating and fabricating

organizing gear for around 30 years, since the start of the Internet period.

From that point forward they have become the pioneers in the Computer

Networking World, continually pushing and propelling different merchants to

grow new advancements and continually pushing the existent advances as far as

possible.

One

of their principal fields is their Switches which are known on the planet for

their multifaceted nature, unwavering quality, and highlights. There are

several current switch lines that Cisco offers: Nexus Switches, utilized

primarily in the Datacenter Environment, Meraki Switches, utilized for Cloud

Management, Cisco Blade Switches, utilized in the Virtualization Environment

and the most utilized and well known Cisco Catalyst Switches utilized in

everyday system tasks.

Cisco

Catalyst switches are ordered in three separate sorts for various applications

relying upon their utilization. They can be utilized in the Access Layer, in

the Core and Aggregation Layers and there are additionally minimized switches.

Each sort of switches has different gadgets to offer. The biggest gathering of

Catalyst switches are the Access Layer Switches. There are twelve changes to

browse. In any case, we ought to consistently remember that innovation pushes

ahead and new and present-day switches are continually supplanting the old

models. Even though the old models like Cisco Catalyst 3750, 3560, and

2960-S/SF arrangement can in any case carry out the responsibility easily, the

new present-day switch models have the strong ground of new highlights that

make them stand apart from the group. The most utilized Access Layer present day

switches are Cisco Catalyst 3650, 3850, and 4500 arrangement.

Going

further, in the system framework, we will meet the Cisco Catalyst Core and

Aggregation line of switches which are truly stuffed with highlights and

potential outcomes to guarantee progressively dependable and loosened up

Network the board. Under this sort, there are most regularly four Catalyst

models to browse, Cisco Catalyst 6800, 6500, 4900M, and 4500X arrangement.

Cisco

Systems are known for their imagination and they chose to build up a line of

switches that would be conveyed in restricted space zones where the ordinary

lines of switches won't have the option to be introduced due to their size. For

this situation, the main Cisco arrangement would be their Cisco Compact line of

switches. Four models fall into this class beginning from Cisco Catalyst

3560-C, 3560-CX, 2960-C, and 2960-CX arrangement. As referenced previously, a

few models are more present-day than the others. For this situation, the new

current models are the CX arrangement switches.

In

the systems administration condition, the scramble for speed, and unwavering

quality are consistent. The most recent pattern in systems administration and by

a long shot the most cutting edge innovation utilized is the Optical

Networking. Cisco switches offer the transfer speed and unwavering quality

genuinely necessary for overhauling the existent Network Architecture. The

advantages of Optical Network Solutions are innumerable. It offers the speed

and limit of supporting the current applications as well as the future

applications that would be created. It offers a repetitive system engineering

fit for supporting even the most mind-boggling business tasks. It offers

diminished expense and multifaceted nature. Since the expense of Cisco Catalyst

Switches are more noteworthy than other seller's switches, numerous IT chiefs

and organizations are attempting to diminish the expenses via looking for SFP

choices to be introduced in their Cisco switches. Anyway, Cisco Systems didn't

permit the utilization of outsider SFP modules in their switches until an

answer was found. On the off chance that an outsider handset is embedded in the

switch's GBIC port, a blunder message will happen to say that a non-bolstered the handset has been distinguished and the GBIC port will be impaired. This happens

because when an outsider handset is embedded in the GBIC port, the switch

peruses various qualities from the new SFP and anticipates that they should be

recognizable. All SFP modules in their EEPROM have various prerecorded

qualities that contain the Vendor name, Vendor ID, Serial number, Security

code, and CRC. Anyway, when it distinguishes that these qualities are not

comfortable it quickly impairs the port as a prudent step. Two undocumented orders

are existing that can be designed to take into account an outsider SFP to be

introduced: "administration unsupported-handset" and after "no disable recognize cause gbic-invalid". These orders would permit the

change to overlook the mistake handicap default conduct and not debilitate the

port when an outsider SFP is identified.

Anyway,

it merits referencing that the fiber-mart.com Blueoptics© handsets are created

and fabricated to work flawlessly with the Cisco Catalyst switches and no

additional setup is required for them to work.

Transceivers

fiber-mart.com

offers a wide assortment of excellent, most recent innovation Blueoptics© Fiber

Optics handsets are proficient for a wide scope of utilizations. Blueoptics©

handsets are created and produced to carry the most extreme exhibition and

unwavering quality to the client. They are made by the most recent norms with

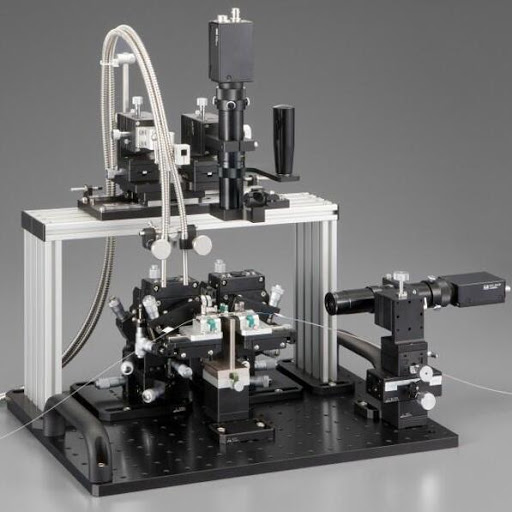

segments by the main producers for the optical alignment machine. They highlight a 5-year

guarantee and lifetime support. What's special about these handsets is the way

that they can be created and fabricated one of a kind for the various systems

administration sellers out there. They are explicitly intended to offer the

most extreme presentation in different system arrangements like server and

capacity arrangements and exchanging and virtualization arrangements.

Blueoptics©

handsets are isolated in various classes relying upon the kind of system the engineering they are required for, anyway, there are most regularly utilized

handsets in every classification.

Blueoptics©

handsets are perfect with over a hundred merchant's hardware however above all

they are good with the broadly mainstream Cisco Catalyst switches.

For

10GB Ethernet organize design the most usually utilized handsets are known as

SFP+ and SFP. These broadly utilized handsets can bolster information rates up

to 16 GB/s (SFP+). In contrast with more established Xenpak and XFP modules,

SFP+ presents the direct append answer for interfacing two separate SFP+ ports

into committed handsets.

For

40GB Ethernet organizes engineering the most ordinarily utilized handsets are

the QSFP handsets. These handsets help the relocation from 10GB to 40GB system

be done consistently and on a similar fiber foundation. They fulfill the most

recent needs in rates and execution.

For

100GB Ethernet organizes engineering the most regularly utilized handsets are

the CFP handsets. These handsets are chiefly utilized in the center system of

Service Providers and Datacenters.

Direct Attach Cables (DAC)

Other

than handsets, fiber-mart.com BlueLAN© offers Direct Attach Cables (DAC) and

Active Optical Cables (AOC). Direct Attach Cables are utilized when interfacing

separate switches in a heap of switches which can be dynamic or latent. Since

the aloof DAC have no dynamic parts inside them, they offer just a direct

electrical association between the two closures. The AOCs are viewed as dynamic

since they encapsulate dynamic optical parts. In this way, it ensures improved

sign quality and gives longer link separation. Then again DAC is made as fixed

get together and they are bought at a precise length.

Even

though many would believe that the finish of the copper links is close, the

story with the Direct Attach Copper Cables is extraordinary. They are still

normally utilized in the systems administration world giving a few preferences

and a few burdens. They give enough information rate to the present

applications, up to 10 GB/s in each channel. They are good with the fiber optic

links and they can be traded effortlessly. They are more affordable than the

optical handsets since they cost less to make and have no optical segments. The

greatest negative attribute of the copper DAC is its weight. Usually, these

links are enormous and massive making them hard to work with. Another negative

perspective is the way that since it's a copper link it's effectively affected

by the electromagnetic impedance. This can in the long run cause a total

framework disappointment.

AOC

is an option in contrast to optical handsets and wipes out the different

interfaces between the handset module and optical link. Like the DAC it offers

a few points of interest and burdens. It needs no gear update and offers a more

prominent data transfer capacity than DAC, up to 40GB/s with QSFP. Given its

assembling procedure, its lightweight contrasted with Direct Attach Cables. AOC

is not fit for transmitting electric flow and it's not exposed to

electromagnetic obstruction. The principle negative angle is the more

significant expense than the DAC.

Follow our Facebook and Twitter for more information about our product.