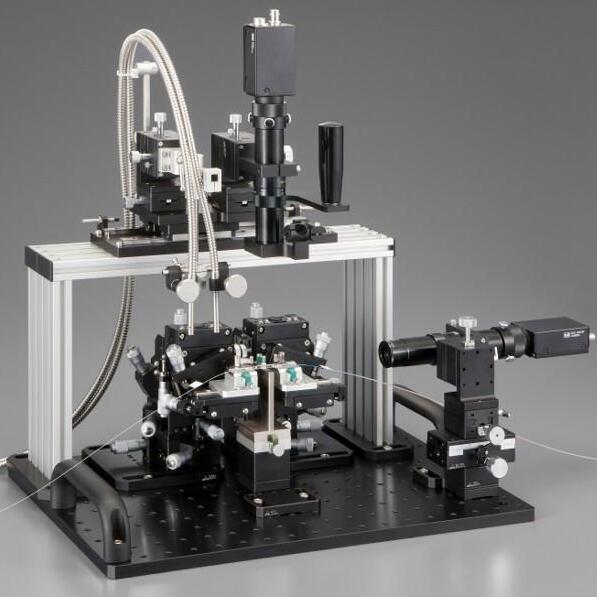

In an optical network, precise fiber alignment with an Optical Fiber Alignment System is required for accurate and dependable data transmission.

The majority of optical networks feature several optical couplings and even

small losses (less than 1%) at these couplings can add up to cause a large

signal loss and subsequent transmission issues. In these networks, coupling

loss minimization is essential.

Before optical system construction or packing, optimal fiber alignment

results in the best coupling efficiency and, thus, the least amount of signal

loss. Reduced power needs due to minimal signal loss translate into fewer

repeaters, cheaper investment costs, and fewer failure incidences.

Typical problems with optical alignment

Stability of alignment

Alignment stability—the capacity of an optical system to retain its

alignment over time and under various environmental conditions—is another

prevalent problem with optical alignment. For optical measurements and

applications to be dependable and repeatable, alignment stability is crucial.

However, several variables, like mechanical wear, temperature changes,

humidity, pressure, or shock, might have an impact on alignment stability.

Thermal compensation, active feedback, strong and stiff mechanical mounts, and

alignment lock mechanisms are some ways to increase alignment stability with

the Optical Waveguide Alignment

System.

Accurate alignment

The degree of agreement between an optical system's desired and actual

alignment is known as alignment accuracy. For optical systems to function well

and be of high quality, alignment accuracy is crucial, particularly for those

that need to have high resolution, sensitivity, or precision. However, there

are several variables that might affect alignment accuracy, including optical

flaws, measurement mistakes, calibration problems, and alignment faults.

Complexity of alignment

The difficulty and amount of time needed to align an optical system are referred to as alignment complexity. The number, kind, and arrangement of optical components; the degree of freedom and adjustability of the mechanical mounts; the optical specifications and needs; and the alignment tools and procedures available are some of the variables that affect alignment difficulty. For optical engineers, alignment complexity can mean higher labor, material, and mistake costs. Simple and modular optical designs, pre-aligned or self-aligning parts, automated or semi-automated alignment systems, and alignment optimization methods can all help to lower alignment complexity. The Optical Fiber Alignment System can ensure proper alignment.

Follow our Facebook and Twitter for more information about our product.