In today’s world, high-speed internet and seamless communication are

made possible by the sophisticated technologies behind optical fiber systems.

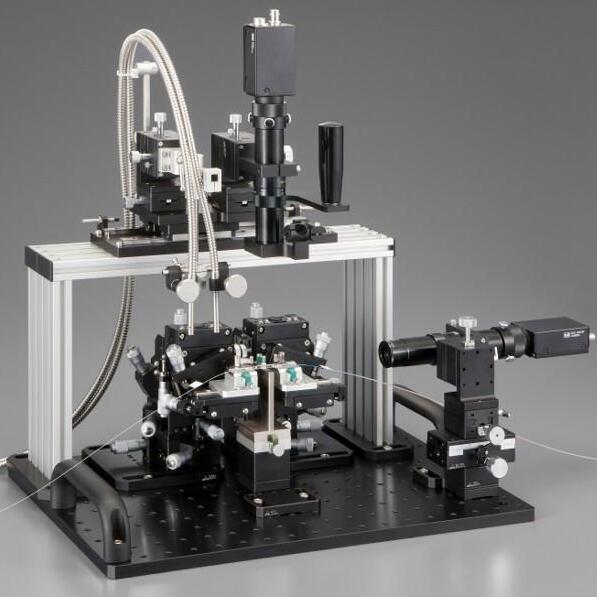

One critical aspect of these systems is the optical fiber alignment system a precise and essential technology

that ensures the effective transmission of data through optical fibers. This

system plays a pivotal role in maintaining the high performance and reliability

of fiber optic networks.

What is an Optical Fiber Alignment System?

An optical fiber alignment

system is a device or set of components used to position and align optical

fibers so that light signals can travel with minimal loss. The system ensures

that the core of each fiber is perfectly aligned, so light can be transmitted

efficiently from one fiber to another. Even the smallest misalignment can cause

significant data loss, signal degradation, or reduced transmission speeds.

These systems are essential during the process of fiber splicing,

where two optical fibers are joined together, or during the assembly of fiber

optic connectors. The precision with which the fibers are aligned directly

affects the quality of the connection and, by extension, the performance of the

entire optical network.

Why is Fiber Alignment Important?

1. Signal Integrity

Optical fibers work by transmitting light signals, which carry data

over long distances. The alignment system ensures that the fibers remain in the

correct position, allowing the light to pass through without interference.

Misalignment can cause light to scatter or reflect, leading to signal loss and

reduced performance.

2. Improved Performance

With proper alignment, optical fiber networks can maintain high

bandwidth and low latency, which are essential for modern communication systems

like high-speed internet, telecommunication, and data centers. The better the

alignment, the less signal degradation occurs, improving overall performance.

3. Cost-Efficiency and Longevity

A well-aligned fiber system reduces the need for repairs and

maintenance caused by poor connections or faulty splices. It helps increase the

lifespan of fiber optic components, making it a more cost-effective solution in

the long run.

Key Components of an Optical Fiber Alignment System

Precision Motors: These are used to fine-tune the positioning of fibers

to ensure they are perfectly aligned.

Alignment Fixtures: Special tools or jigs hold the fibers in place

during the splicing or connector assembly process.

Optical Sensors: These sensors detect the position of the fibers and

help adjust them until they are optimally aligned.

Conclusion

An optical fiber alignment system is a crucial technology in the field of fiber optics, ensuring the reliable and efficient transmission of data across networks. By guaranteeing that optical fibers are precisely aligned, these systems help maintain the quality, performance, and longevity of fiber optic communication systems. As the demand for faster and more reliable internet continues to grow, the role of fiber alignment technology will only become more critical.

Next: PM Fiber Patch Cables: Precision Connectivity for Advanced Optical Networks