Precision is crucial in the ever

changing field of communication technology. The need for quicker, more

dependable connections is only increasing, whether it is via 5G networks,

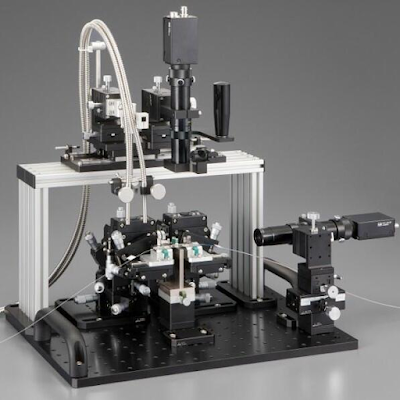

high-speed internet, or data centres that fuel the cloud. The Optical Fiber Alignment System is a

quiet but significant invention that is working behind the scenes.

An optical fibre alignment system: what is it?

A high-precision method for

aligning optical fibres with nanometre accuracy is called an optical fibre

alignment system. By ensuring that the cores of two fibres are precisely

aligned, these systems reduce insertion loss and increase signal strength. Even

the most sophisticated fibre networks will experience inefficient transmission

in the absence of precise alignment.

Why is Alignment Important?

Networks are under more strain

than ever before due to the exponential increase in data consumption—think

video streaming, remote work, IoT, and AI. Accurately aligning optical

components has a direct impact on:

Transmission Speed: Data transport may be slowed down by

misalignment.

Signal Quality: Signal loss is decreased by precise alignment.

Network Reliability: Outages and error rates are increased by

faulty connections.

Optical Waveguide Alignment System

The Optical Waveguide Alignment System goes beyond conventional

alignment, which just considers fibres. It is intended to align integrated

photonic waveguides as well as optical fibres, which are crucial parts of

photonic chips that manage light-based data transfer on a micro scale.

These systems are necessary in:

Faster, smaller, and more

energy-efficient circuits are made possible via silicon photonics.

In quantum computing, accuracy

cannot be compromised.

Advanced Sensing: When photonic integration is needed in

aeronautical or healthcare applications.

Optical Waveguide Alignment Systems are driving innovation in a variety of sectors by guaranteeing nearly flawless coupling between fibres and waveguides.

The foundation of tomorrow's communication infrastructure is made up of Optical Fiber Alignment System and optical waveguide alignment systems, which may enhance the quality of your video conversations and enable cutting-edge technologies like photonic chips and quantum computing.