A little but crucial step in the manufacturing process, crimping

fortifies the cable assembly and shields the fiber. Reliability and long-term

performance are directly impacted by maintaining the optical connection, which

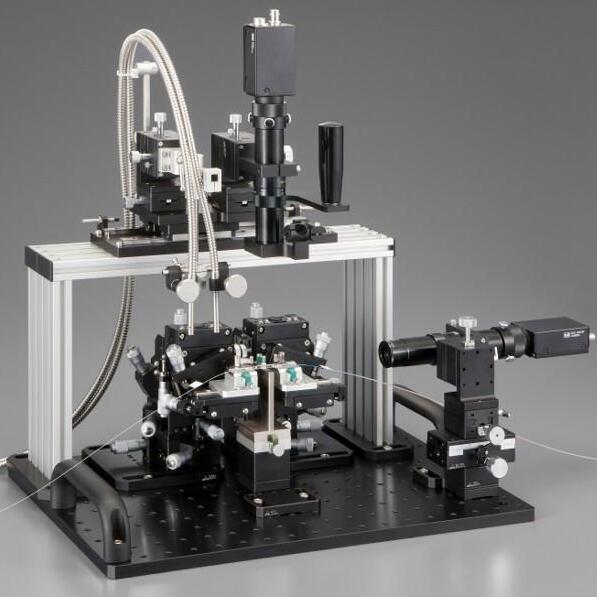

is made possible by using proper crimping procedures with a Fiber Crimping Machine.

Suggestions for optimal crimping methods

The crimping procedure comprises three components: the connector body, a

metal crimping sleeve or ring, and the material to be clamped, which is often

the cable's strength part, aramid yarns. Use these pointers to enhance your

crimping processes:

Use the right crimp tool:

To get the optimal crimp and maximum pull force for that assembly, the

connection manufacturer specifies the die set, crimp sleeve, crimp force, and

crimp tool for each connector body. It is vital to utilize the appropriate

instruments and parts. The experts at the connection maker considered

mechanical tolerances while designing this "match made in

heaven." Crimping and Fiber Polishing Film increases

the contact surface area. These particulars increase the assembly's maximum

draw force.

The incorrect die set or crimp tool might cause harm to the cable

assembly since the crimp will probably be too light or too hard. The connection

may be crushed by a forceful crimp. Glass optical fiber damage is also a

possibility if this structure sustains damage. As an aside, you can utilize an

automated crimp tool, which provides repeatability and produces superior

process control with less operator fatigue, or the manual crimp tool that is

recommended by the connection maker.

Teach your operators–Remember,

every part needs a unique Fiber Crimping Machine, die, and sleeve. Never

combine different components! There may be ten or fifteen die sets with

different tools on some manufacturing lines; the operator has to know which

tool to use for each connection. Here's some advice: Give your tools a number

or color code to help you recognize them for each unique cable assembly

product. By doing this, you can make sure that your operators always utilize

the appropriate tool.